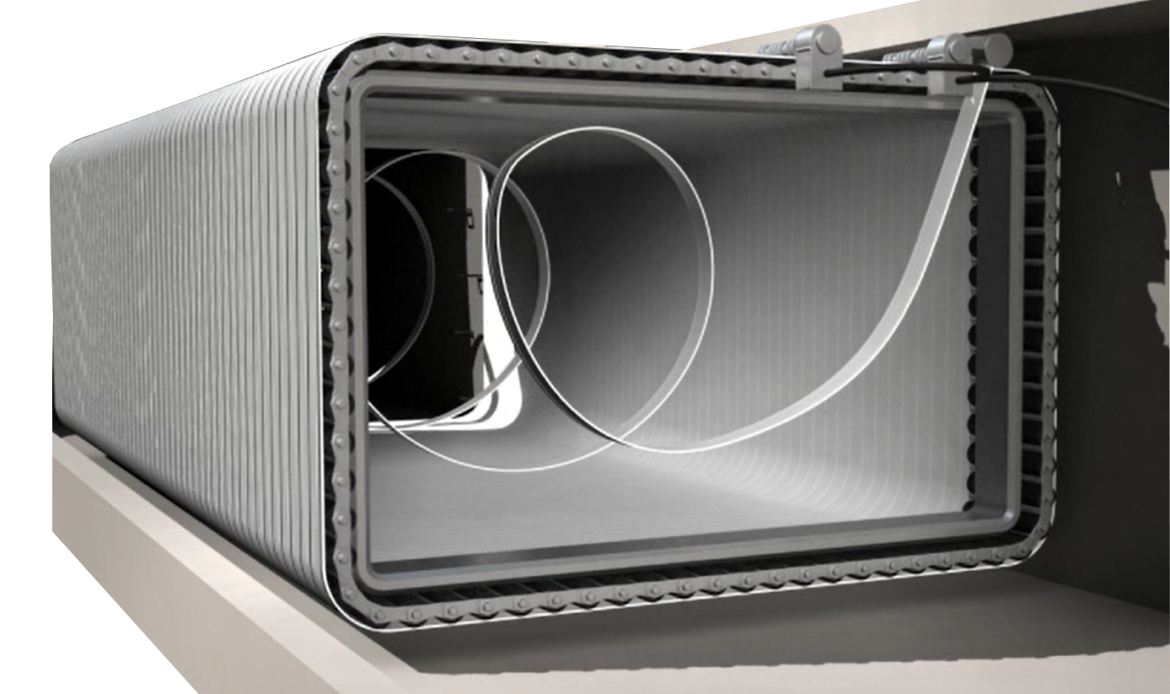

SPR™ Spiral Wound Lining

32″ – 200″+ Pipe Lining Round & Non-Round Shapes 100% Trenchless

The Round & Non-Round Liner for Large Diameter Pipe Rehabilitation

SPR™ is a Spiral Wound pipe lining method for large diameter sewers, storm drains and culverts. SPR™ lines both round and non-round shapes, providing fully structural rehabilitation.

The PVC profile strip is wound into the pipe by a traverse winding machine. The machine travels the length of the pipeline while constructing the liner at a fixed diameter. Grout is then introduced to fill the annular space; either part of the structural liner or just as a gap filler to uniformly transfer loads onto the liner. Grout type depends upon dimensions of the pipe and overall project conditions.

SPR™ Lining Process

The SPR™ Spiral Wound process is a trenchless rehabilitation solution for restoring the hydraulic efficiency, reliability, and integrity of aging sewers, storm drains, and culverts. SPR™ lining occurs along a guide-frame constructed to mirror the pipeline’s shape. These shapes can be anything from a box, horseshoe, teardrop, arch etc. The SPR™ machine traverses the pipe while pulling PVC profile along to construct the trenchless pipe liner.

Once winding is completed, grout is introduced between the Spiral Wound liner and host pipe. Grouting occurs in lifts through a series of ports installed within the liner. Once grouting is finished, the end result is a fully structural rehabilitated pipe.